- HOME

- >

- Our challenge

- We manufacture BRAITEN TUBE, which is used in cars, gas equipment, water heaters, and many other products essential for life.

Each year, we manufacture about 120,000 km of BRAITEN TUBE, which would go around the earth three times if laid end-to-end.

Through product manufacturing that considers energy savings and safety, we continue to develop innovative technology while looking abroad to create a better society.

Five policies

- Specialized manufacturer of thin pipe

- As a specialized manufacturer of small diameter, thin-walled, precision steel pipes, we make pipes in every diameter from 4.0 through 25.4 mm.

To help solve our customers’ problems, we use many materials, including general and high-strength steel plates, surface-plated steel plates, aluminum alloys, stainless steel, and titanium.

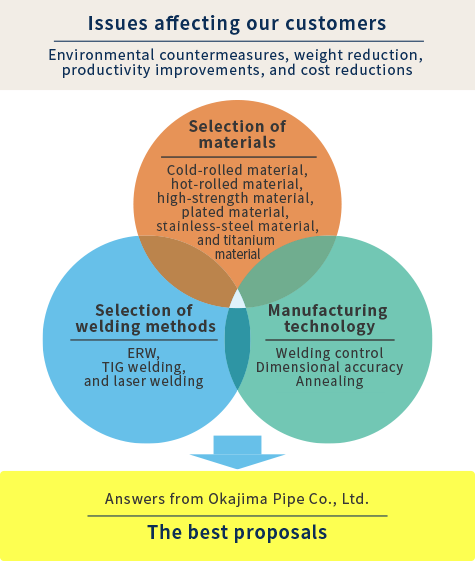

- We work to solve the problems of each customer.

- Environmental countermeasures, weight reductions, productivity improvements, and cost reductions.

After carefully listening to the customer’s various issues and requests, we choose the best materials, welding methods, and manufacturing technology.

We guide each customer to the solutions for all their problems through special specifications.

- We develop innovative technology while looking abroad.

-

1950s Started manufacturing coil-wound welded steel pipe 1960s Introduced a high-frequency welding machine made in the US

Exported steel pipe for furniture to the US1970s Introduced an automated drawing machine made in Germany 1980s Started general sales of coil-wound welded steel pipe

Built a pipe-making factory near Bangkok, Thailand1990s Introduced pipe-making equipment made in Italy 2000s Exported coil-wound steel pipe with a diameter of φ4.76 mm to China and Iran 2010s Built a pipe-making factory near Jakarta, Indonesia

- Teamwork that combines the abilities of each person

- Combining everyone's knowledge and skills, matter how limited or minor, can make an enormous difference.

To achieve this difference, employees must be multidimensional.

By providing experience with various positions and duties, we develop senior managers that can make judgements and decisions on their own, so that the organization can respond quickly and flexibly to changes in the environment.

- Harmony with the region and environment

-

We aim to harmonize all our business activities with the environment based on Okajima Pipe's management approach of "take care of nature and the environment". Everyone that works at and for Okajima Pipe meets their societal responsibilities by continually solving environmental issues, saving resources, and conserving energy to reduce their environmental impact.

The future of Okajima Pipe

A message on our 80th anniversary

Okajima Pipe celebrated it is 80th anniversary in April 2020.

In 1940, we started manufacturing welded steel pipes for bicycles in Yokosuka-machi, Chita District, Aichi Prefecture (currently Tokai city). Since then, we have expanded our business activities to include the manufacturing and sales of steel pipes for the mechanical structures of cars, gas equipment, and other products.

We have grown into a company that supports people's lives.

Although there were many challenging times, thanks to the support and cooperation of our clients, stockholders, and everyone that supported our company, we were able to reach this milestone, for which we are extremely grateful.

We again recognize the spirit of our corporate philosophy, “Develop innovative technology and live up to the expectations of our customers”, and together we strive for manufacturing that breaks down traditional barriers.

We sincerely look forward to your continued patronage.

- Founder of Okajima Pipe Co., Ltd.

- Factory interior in the 1950s

- View of the factory at the company’s founding